Why the Water sector needs protective coatings?

Ensuring safe and sustainable access to drinking water is a critical priority in the water industry. At Northpoint, we specialise in providing high-quality protective coating for the water sector that meet the stringent requirements of the Drinking Water Inspectorate (DWI) in the UK. Our coatings are designed to enhance the safety, durability, and efficiency of pipe systems, contributing to a reliable water supply infrastructure.

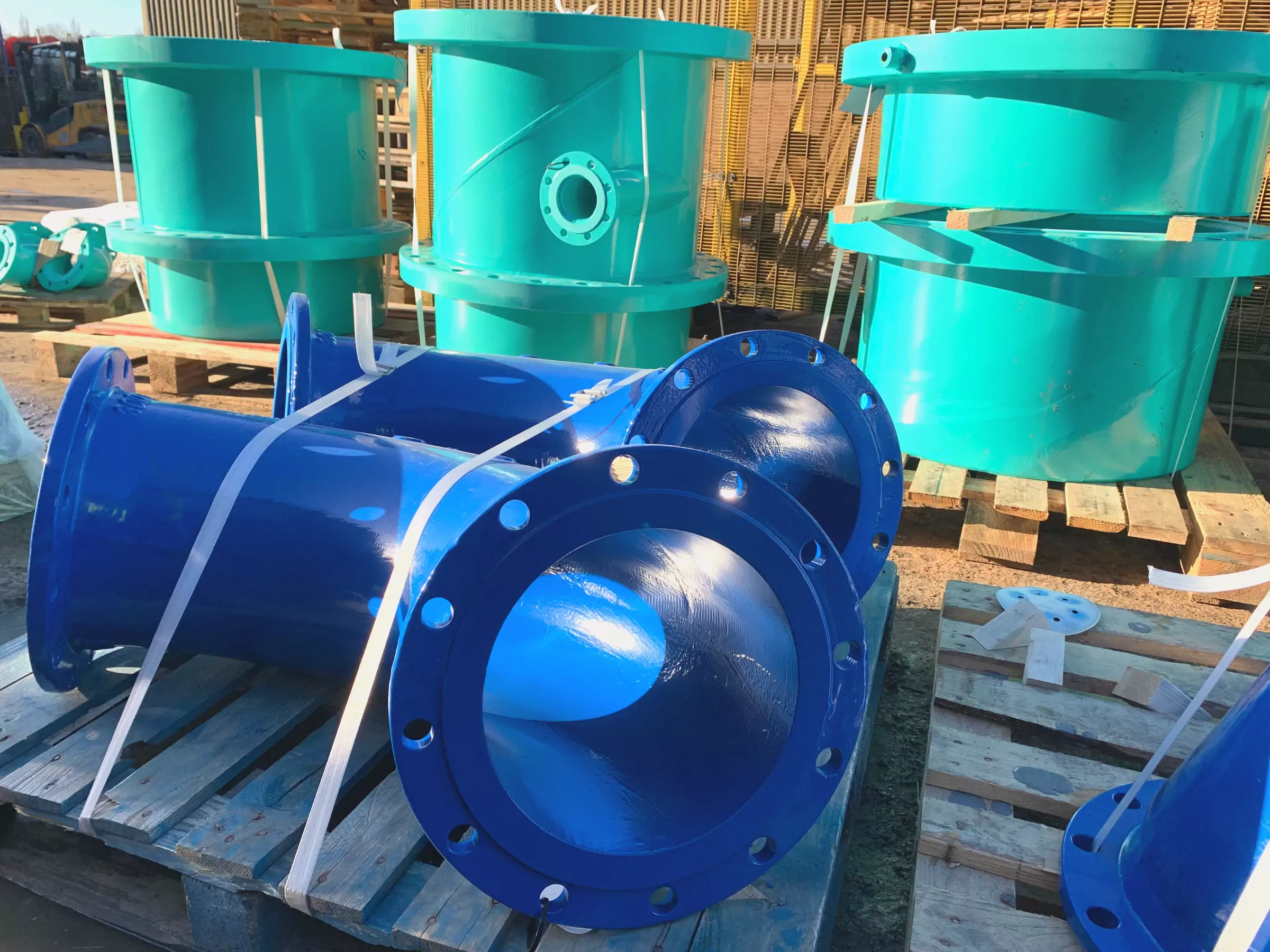

With AMP8 initiatives emphasising sustainability and resilience, we are uniquely positioned to provide protective coating for the water sector, with our extensive experience and industry-leading solutions. Our Fusion Bonded Epoxy (FBE) coatings, including Aqua Green, and Blue EN545, as well as advanced wet paint systems, provide exceptional protection against corrosion and wear, ensuring the longevity and integrity of water systems.

Northpoint holds various approvals for coatings in the water sector.

- WRAS approval for Resicoat products blue, black & green

- DWI approval for Resicoat Aqua Green

- DWI approval for Eurokote 468 Thixo

Partner with us to implement innovative coating solutions that safeguard water quality, align with regulatory standards, and advance the goals of a sustainable water network.

Process Northpoint would go through to coat

In the water sector, safety, durability, and compliance are paramount. Our advanced coating process ensures that every pipe, fitting, or component we treat meets the highest industry standards, safeguarding water quality and system longevity.

Here’s how we deliver premium coating solutions tailored to the unique needs of the water industry: